Custom injection molders use ultrasonic welding as a secondary operation when two thermoplastic parts need to be joined together. The bonding of two parts into one may be specified when there is a complex design that is not feasible to mold as one part – so the part design is changed to be manufactured as two or more parts that must be assembled. This is determined early in the Design for Manufacturing phase (DFM) of new product development.

In other situations, the need for part assembly after molding occurs when parts must be assembled around other components such as motor housings or enclosures. Ultrasonic welding is most often the go-to method of joining plastic parts because it is a fast and efficient process that creates a strong seal and offers many advantages, including simplifying part design, providing hermetically sealed enclosures, eliminating the need for fasteners, adhesives or tapes, and more.

How Does the Ultrasonic Welding Process Work?

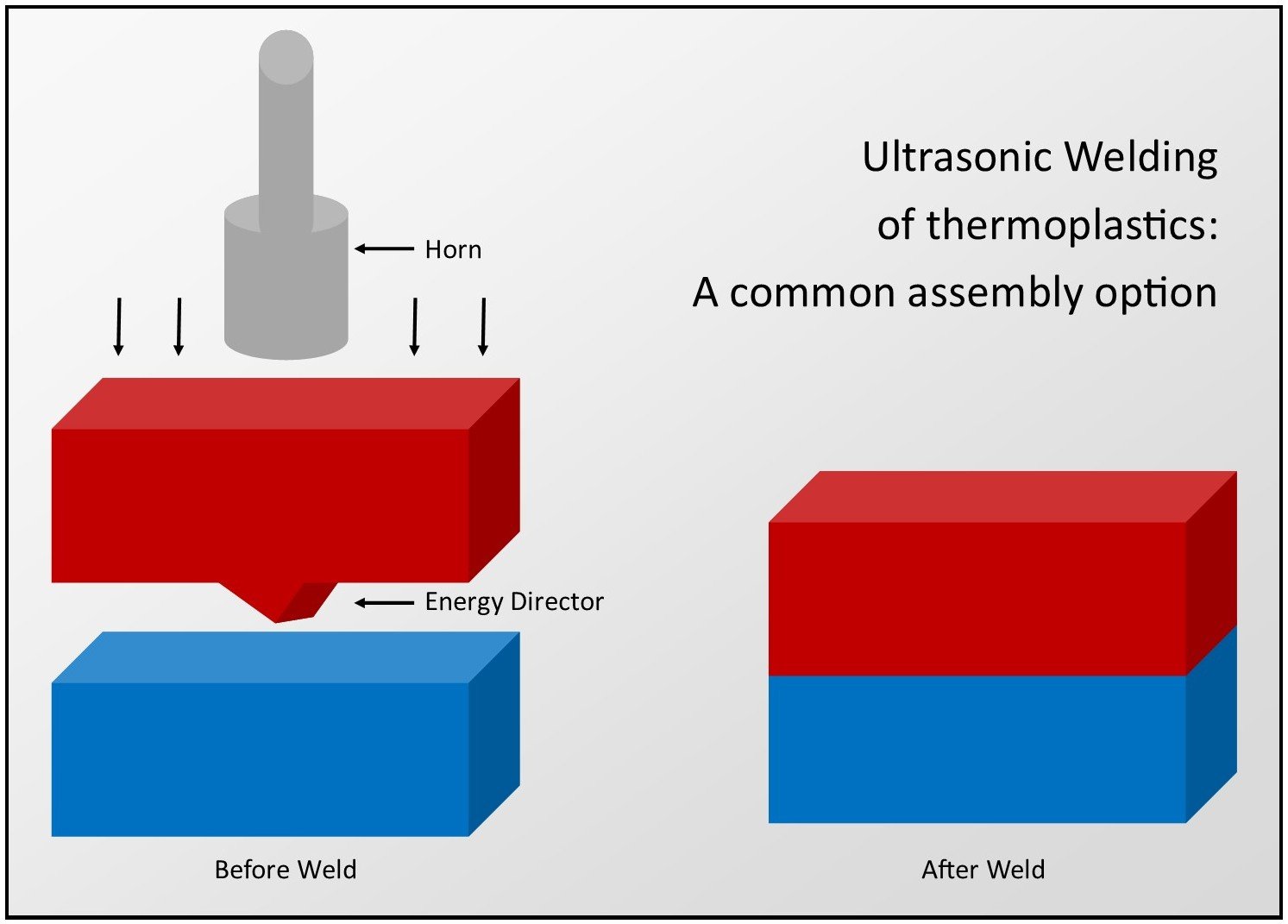

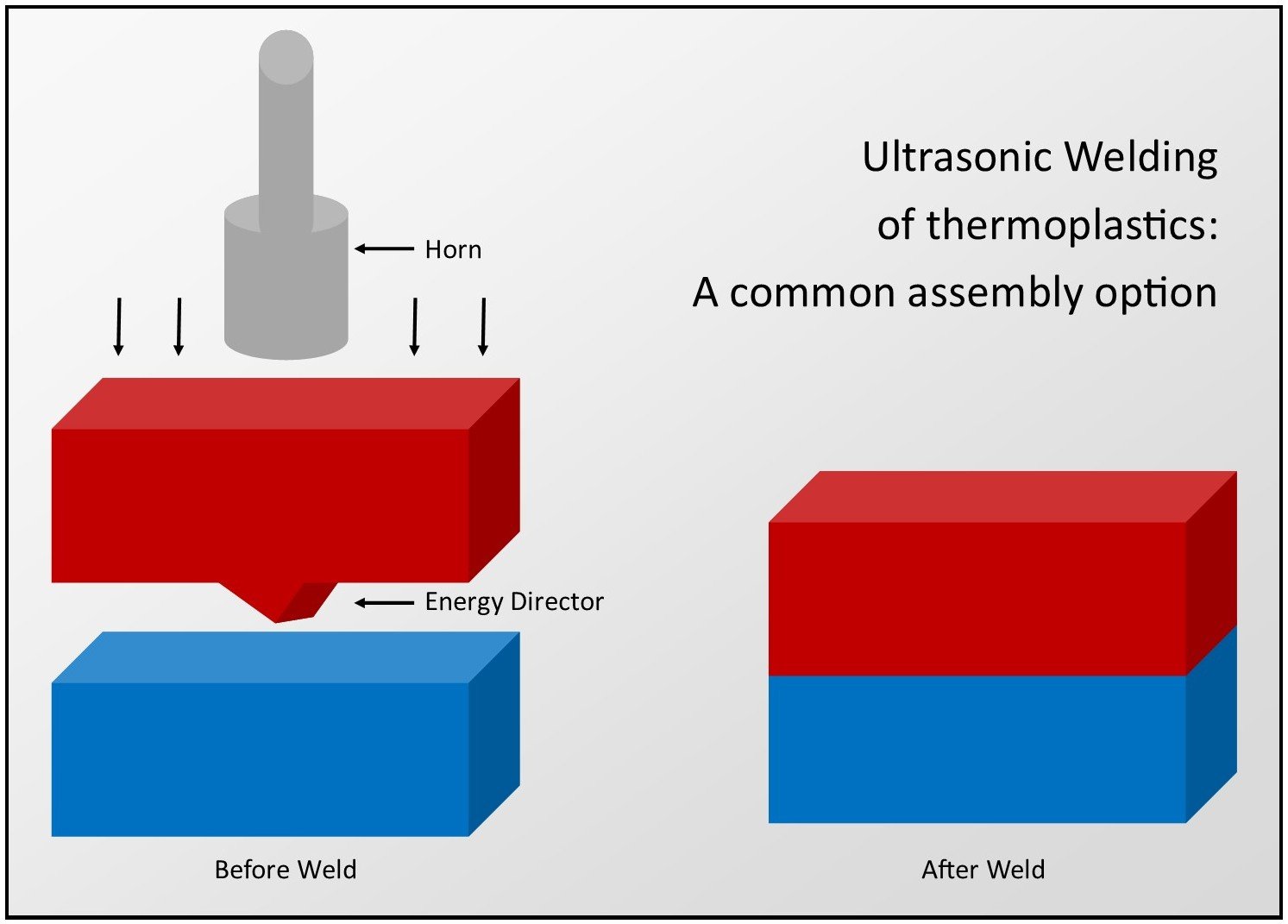

The ultrasonic welding process works by fusing plastics together on a molecular level. The welding machine creates high-frequency sound vibrations that produce frictional heat through a device called a horn. When touching one of the plastic parts with a specific amount of pressure, the heat transfers to the second part, and the contact area between the two parts soften. When the vibration stops, the plastic solidifies, bonding the two pieces together. Ultrasonic welding is often used in mass production because the welding times are relatively short – often less than 1 second. It is also a very repeatable and reliable process that is easy to automate.

It is important for designers to consider product requirements when parts are being designed for ultrasonic assembly. Joint design and resin selection decisions are impacted by these inputs.

It is important for designers to consider product requirements when parts are being designed for ultrasonic assembly. Joint design and resin selection decisions are impacted by these inputs.

Here are the most common questions to ask prior to designing joints for ultrasonic assembly of parts:

- What types of materials are being used?

Some resins are more weldable than others. - What is the overall part size and configuration?

This is critical for identifying the location and type of joints. Ultrasonic energy is not great enough to produce large joints greater than 250mm in length. - What are the final requirements of the part?

- Is a structural bond desired? If so, what loads does it need to resist?

- Is a hermetic seal required? If so, to what pressure?

- Does the assembly require a visually attractive appearance?

- Is flash or particulate objectionable inside and/or outside the weld or joint?

This is important information that your injection molder will ask that will help to optimize joint design, tool design, part quality, and manufacturing processes. Clarification of these requirements in the early stages of development will prevent design change delays, costly mold changes, and missed product launch dates.

Polymer Material Selection: Where Ultrasonic Welding and Resin Selection Meet

Ultrasonic welding requires specific areas of the parts to soften but not melt with increased temperature. This is why thermoplastic polymers and not thermosets are used for this application. Two main types of thermoplastic polymers exist – amorphous and crystalline. Amorphous polymers work best when using the ultrasonic welding process. Here’s the difference:

Amorphous polymers do not have an organized molecular structure or a defined melting point. When heated, they gradually soften as they pass from a rigid state, through a glass transition, into a rubbery state, followed by a liquid flow in a true molten state. Solidification is likewise gradual. Crystalline polymers have a more organized molecular structure which causes the material to absorb vibration energy before it can be passed through to the joint area. This means more power is needed to weld them, and they have a sharper melting temperature. This causes difficulty in making a quality weld without damaging the parts. ABS, Acrylic, Polycarbonate, and PVC are amorphous polymers – with little or no crystalline structure, they are ideal for ultrasonic welding. Polyethylene, Polypropylene, Polyester, and Nylon are semi-crystalline and are still used in the ultrasonic welding process but are more difficult to weld.

Amorphous polymers do not have an organized molecular structure or a defined melting point. When heated, they gradually soften as they pass from a rigid state, through a glass transition, into a rubbery state, followed by a liquid flow in a true molten state. Solidification is likewise gradual. Crystalline polymers have a more organized molecular structure which causes the material to absorb vibration energy before it can be passed through to the joint area. This means more power is needed to weld them, and they have a sharper melting temperature. This causes difficulty in making a quality weld without damaging the parts. ABS, Acrylic, Polycarbonate, and PVC are amorphous polymers – with little or no crystalline structure, they are ideal for ultrasonic welding. Polyethylene, Polypropylene, Polyester, and Nylon are semi-crystalline and are still used in the ultrasonic welding process but are more difficult to weld.

- Materials must be chemically compatible to generate a molecular bond.

- Dissimilar thermoplastics may be compatible only if their melt temperatures are within 40 degrees F and they are of like molecular structure.

- Only similar amorphous polymers have a good probability of being welded to each other. Major amorphous thermoplastics include ABS, styrene, acrylic, PVC, and polycarbonate. Some semi-crystalline thermoplastics that can be ultrasonically welded include acetyl, nylon (polyamide), polyester, polyethylene, polypropylene, and fluoropolymers.

Resin characteristics that control process requirements

- Hygroscopic resins

- Mold release agents used

- Lubricants

- Plasticizers

- Fillers

- Flame Retardants

- Regrind Percentage

- Pigments

- Resin Grade

Hygroscopic resins

These resins have a tendency to absorb moisture from the atmosphere and can seriously affect weld quality. Nylon happens to be the material used that is most impacted by this characteristic. If parts are allowed to absorb moisture, the resin can become degraded at the joint interface. This can result in difficulty obtaining a hermetic seal, leave a poor cosmetic appearance, or reduce weld strength. For the best results, it is recommended that welding be completed as soon as the parts are molded. If parts need to be stored prior to completion, make sure that the parts are protected from moisture by storing them in plastic bags with a desiccant. Even though resins are typically placed in a dryer prior to molding, finished parts can still absorb moisture.

Mold release agents

During production, mold release agents are usually sprayed directly onto the surface of the mold cavity. This helps to reduce friction between the part and the cavity walls, allowing the parts to eject more easily. The release agents can be transferred to the joint interface, where they may lower to the coefficient of friction of the material being welded. This affects heat generation at the joint interface and interferes with the fusion of the melted surfaces. Choosing a mold release agent with properties that will not interfere with ultrasonic welding is important.

Lubricants

Waxes, zinc stearate, stearic acid, aluminum stearate, and fatty esters are added to resins to improve flow characteristics, making it easier to process. These cannot be removed and will reduce the coefficient of friction where the parts join together, reducing their ability to be welded.

Plasticizers

Plasticizers increase the flexibility and softness of the resin and have a tendency to migrate to the joint of a welded part after a period of time. This results in a weakened bond at the joint.

Fillers

Glass fiber, talc, carbon fiber, and calcium carbonate are added to the resin to produce desired physical properties such as dimensional stability or added strength. Some mineral fillers such as glass or talc can actually enhance the weldability of some thermoplastics because they improve the resin’s ability to transmit vibrational energy. Problems can arise, though if the ratio is too high. Less than 30% filler content – filler accumulation at the weld joint can reduce weld strength.

Flame retardants

The flame retardants added to the resin to inhibit ignition or modify burn characteristics can have adverse effects on a resin’s ability to be welded. This must be compensated for by modifying the joint configuration where parts interface and increase ultrasonic energy levels.

Regrind percentage

When using recycled resin, no more than 10% regrind is recommended for the best results.

Pigments

Most colorants do not interfere with ultrasonic assembly; however, black or white parts require more pigment, which can cause some problems. Titanium dioxide (TiO2) is the main pigment used in white parts and can act as a lubricant and can inhibit weldability if used in high loadings over 5%. Black parts may be pigmented with carbon, which can also inhibit weldability. Adjusting welding process parameters can be a solution.

Resin grade

Both materials to be welded should have similar molecular weight and melt temperatures within 40F (22C) of each other. Different grades of the same material can have very different melt temperatures.

Joint design requirements for Ultrasonic Welding

For optimum assembly results, the three basic requirements when designing a joint are a uniform contact area, a small initial contact area, and a means of part alignment.

Uniform Contact Area

The mating surfaces of the parts should be in intimate contact around the entire joint, ideally on one plane. The horn should also make contact directly over the joint area in order to focus the transmission of the mechanical energy to the joint area.

Small Initial Contact Area

The initial contact area between the mating surfaces should be small in order to concentrate and decrease the total energy and time needed to start and complete the melting of the mating parts. By minimizing the time the vibrating horn remains in contact with the part, you reduce the potential for scuffing, and since less material is moved, less flash is generated. This is achieved by what is called an energy director, which is typically a triangular-shaped protrusion that is molded into the part and runs around the entire joint.

Means of Alignment

A means for aligning the mating parts should be provided for a precise joint. Features such as pins and sockets, steps, or tongues and grooves should be used for alignment rather than the vibrating horn and fixture. This will ensure proper, repeatable alignment and avoid marking.

What are the Benefits of Ultrasonic Welding?

Ultrasonic welding of plastics is a reliable, consistent, repeatable process that provides a clean, strong, integral bond. The benefits make it widely accepted in many industries, including automotive, medical, electrical, electronics, communications, appliances, and consumer products.

Ultrasonic welding of plastics is a reliable, consistent, repeatable process that provides a clean, strong, integral bond. The benefits make it widely accepted in many industries, including automotive, medical, electrical, electronics, communications, appliances, and consumer products.

The savings realized by this process include:

- Lower energy usage than other joining techniques

- Material savings -no need for consumables like glue or

mechanical fasteners - Labor savings with lower assembly cost through automation

- Rapid dissipation of heat shortens production time

Injection molders who offer this value-added service work closely with design engineers and ultrasonic welding experts to find the most cost-effective solution yielding quality parts. Understanding design requirements for parts to be assembled can allow for a well-designed tool that produces superior results. Avoid NPI delays and tooling rework by involving your injection molder upfront.

Do you have a new product with multiple components needing assembly? Contact Ferriot to help you ensure a successful product launch.