A practical way to provide design flexibility – A smart way to reduce cost

Gas assist injection molding (GAIM) is an enhanced injection molding process often applied for complex parts, large parts and parts requiring an attractive, cosmetic finish. The types of parts benefiting most from this process include:

- large panels

- enclosures

- handles

- doors and bezels

- tube or rod shaped parts

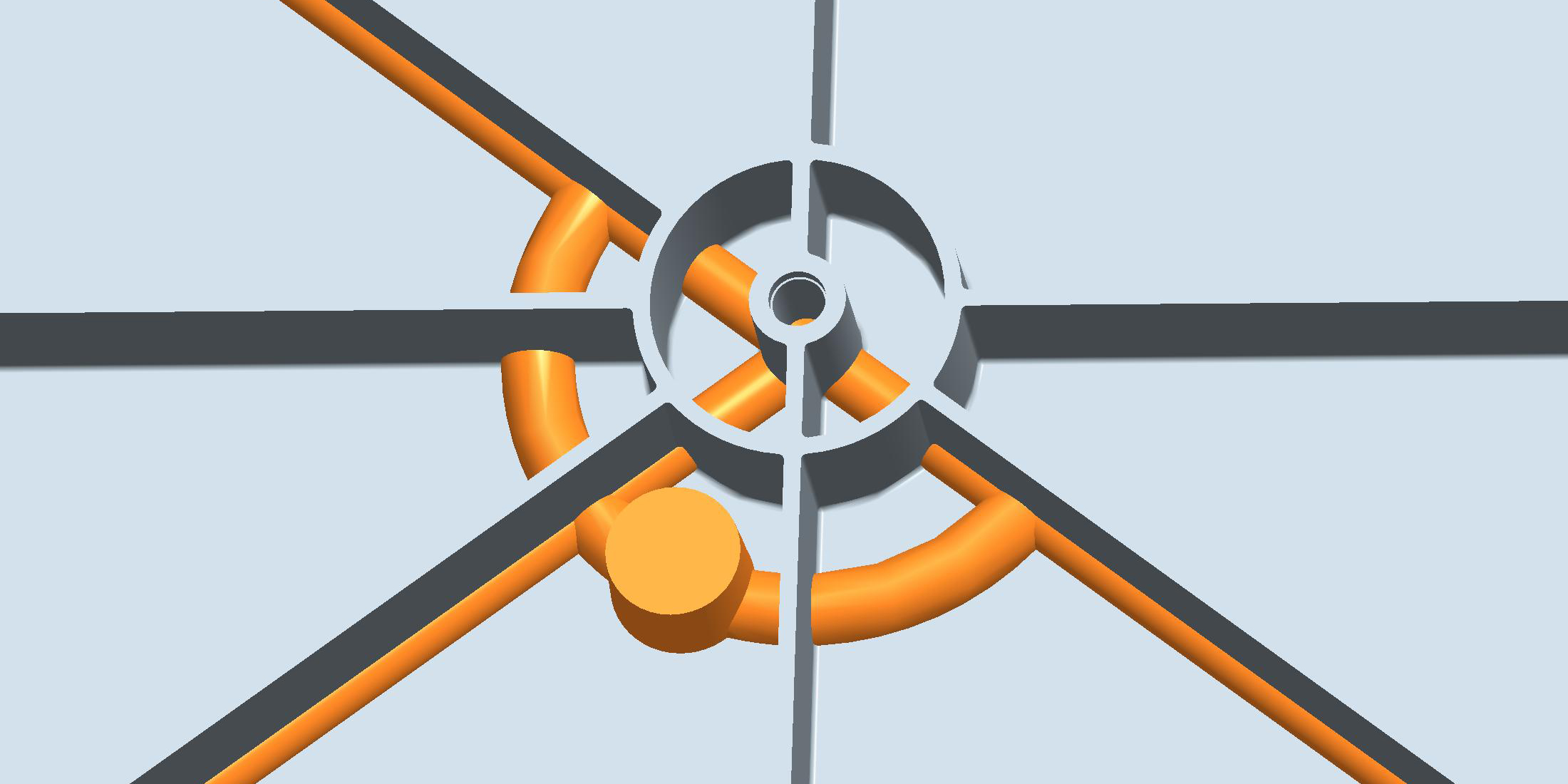

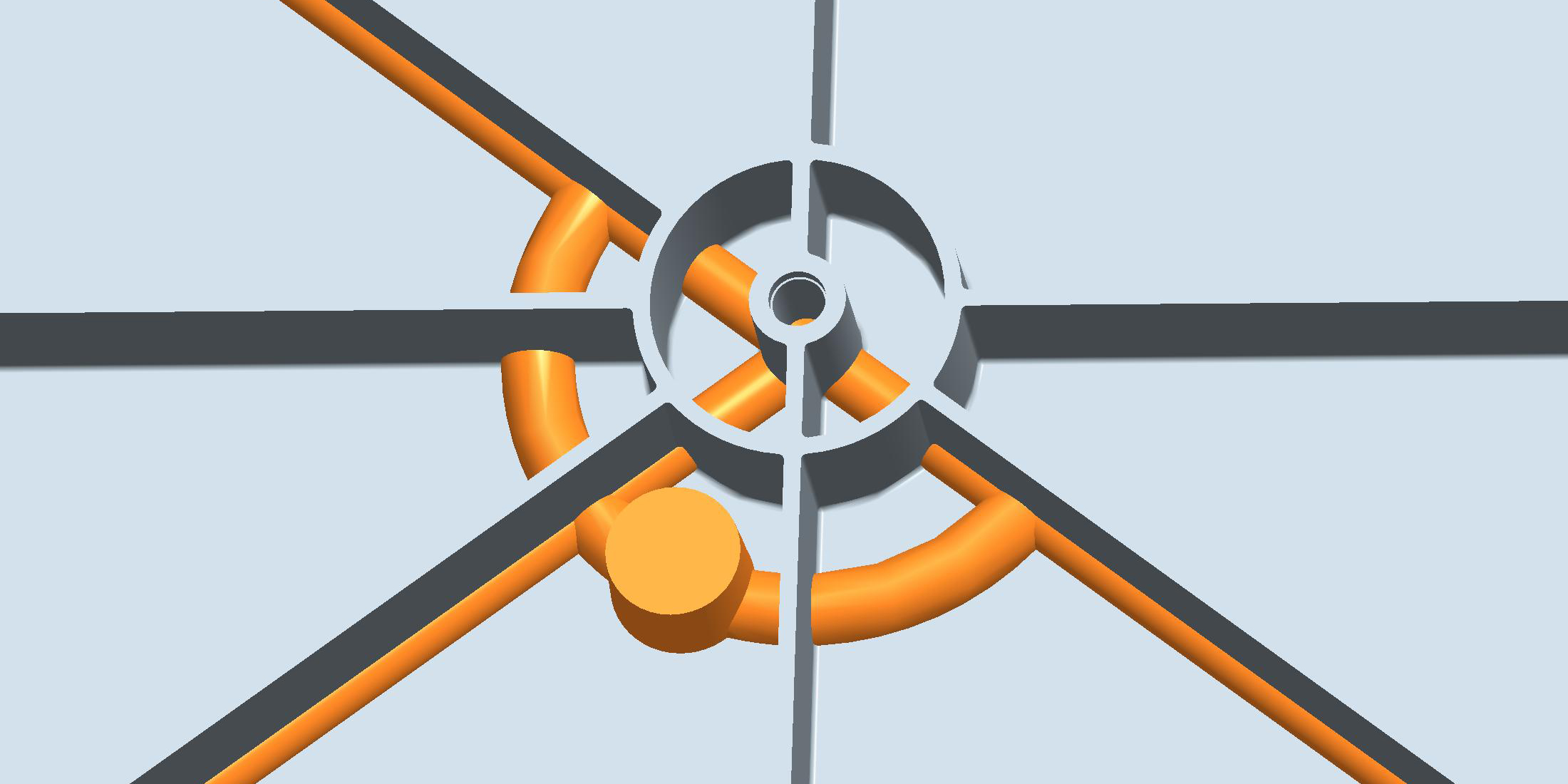

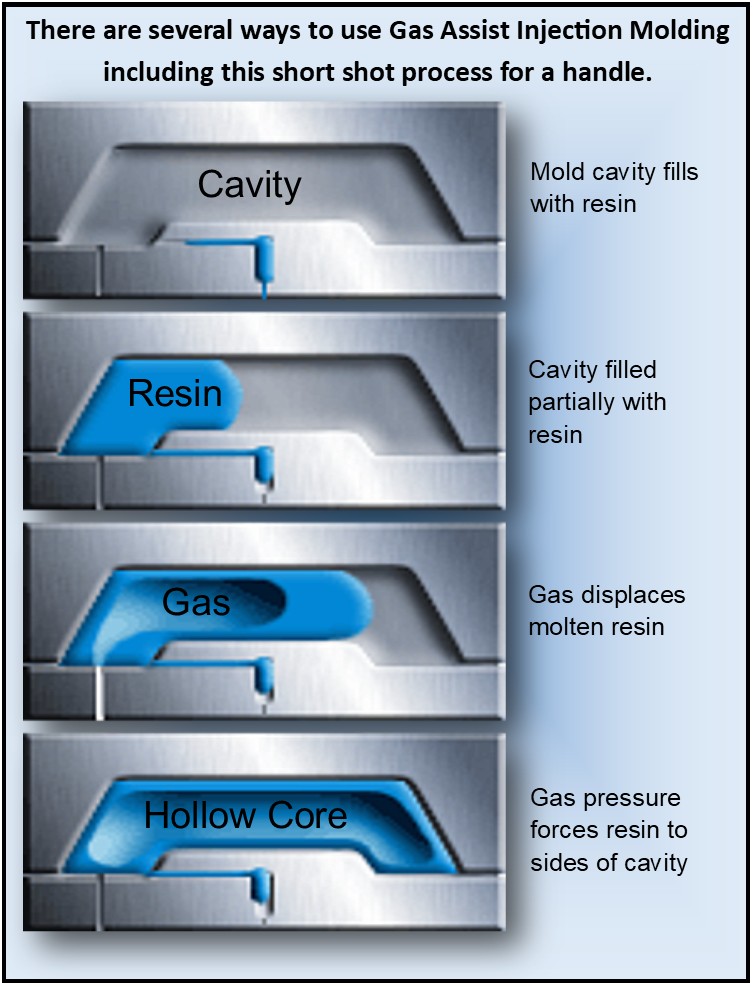

The gas assist process is introduced at the finish of the mold filling stage while the resin is still liquid. Pressurized gas (usually nitrogen) is used in place of pack pressure from the molding machine. The pressure from the gas completes the filling of the mold cavity, forcing an even distribution of molten resin against the mold. The gas is held inside during the entire cooling phase and then is vented, leaving a hollow void. For internal gas-assist molding, the void is inside the plastic. For external gas assist molding, the void is on the outside surface, typically the back side of a part.

Benefits? There are many.

The gas-assist process gets results when part design elements make the part difficult to manufacture using straight injection molding. GAIM allows for more design flexibility while still being able to provide these benefits:

- Thin-walled parts with greater strength and rigidity

- Creation of hollowed out areas, reducing part weight

- Reduction of molded in stress for improved dimensional stability

- Better surface finish with no sink marks

- Less part shrinkage and reduced warpage

Design Advantages with Gas Assist

1. Complex Designs

For the design engineer, using GAIM expands design options and helps to minimize design changes to make the part manufacturable using injection molding. One of the greatest benefits is the ability to produce complex parts. Oftentimes with straight injection molding, parts having different wall thicknesses are molded separately and assembled later.

GAIM allows multiple parts to be combined into one, reducing the need for secondary assembly processes – even if the parts have different wall thicknesses. This is because gas-assist allows heavy wall sections to intersect thinner ones. Support ribs and bosses can achieve tighter tolerances and be designed larger without fear of sink marks. Gas channels are directed toward these areas and the consistent pressure during the cooling phase eliminates sink marks, associated with these support features, on the front side of the part.

2. Metal Replacement

Gas-assist allows production of thin-walled components that have solid but hollow areas. The resulting strength and lightweight part can often replace metal fabricated or die cast parts, and reduce product cost.

3. Large parts

The introduction of gas pressure aids in mold filling, providing uniform pressure throughout the part that lasts through the cooling stage. The result is a part with less shrinkage and reduced warpage. Part weight can also be reduced by creating hollowed out areas.

4. Cosmetic finishes

Where an attractive finished surface is required, gas-assist prevents sink areas which eliminates or at least minimizes secondary operations to improve part appearance including sanding and priming.

5. Hollow parts

The gas can create hollowed out areas within parts like handles, which decreases part weight and still provides strength.

Cost Benefits with Gas Assist

1. Extended Tool Life

With gas-assist, lower clamping force is required because lower pressures are used. This results in less mold wear extending the life of the tool.

2. Less Energy Cost

With lower clamping force required, larger molds can be used in smaller presses. Smaller presses consume less power and help to decrease the cost of manufacturing the part.

3. Less Machine Time

A more rapid cooling period helps to reduce cycle time which in turn lowers manufacturing expense per part.

4. Lower Material Cost

Less material is used to produce the part because hollow areas inside of the part are created with the gas and with less resin used, part cost is lowered.

5. Quality Results

With gas-assist injection molding, the process is typically easier to control than conventional injection molding. A dependable, repeatable process provides consistent production results and less waste.

Gas Assist Tool Design

If you want to achieve high quality results, make sure you get the tool design right.

Regardless of what injection molding process will be used, it is important to engage your molder during the early stages of part design in the design for manufacturing (DFM) phase. Tooling cost, timeline and resulting part quality will be directly impacted by the quality and efficacy of the tool. When determining the optimal way to mold a part, engineers will consider all product requirements including application, resin selection and cost considerations. Mold flow analysis is used to find design constraints so that adjustments can be made. When the tooling engineer determines gas-assist is the best solution, the tool will be designed with gas channels built in to the mold that will allow the addition of nitrogen gas during the molding process. Determining your molding method early will conserve tooling cost and help to maintain project timelines. Getting your molder involved early will be critical to a cost effective, high-quality product.

To learn more about this process or to receive assistance with your project, contact Ferriot.

Learn more…