In Part 1, we discussed mold flow analysis (MFA) and the ways Ferriot uses it to improve the tool design process and, ultimately, the quality of the final custom injection molding we perform for our customers. In this segment, we’ll address questions about the Ferriot team’s experience using MFA, the types of problems and pain points that have been discovered and resolved, and an example of savings that one customer experienced as a result.

Liz: Is this a pretty common process in injection molding with other companies? Or is it something that Ferriot feels is a strength that we bring to the customer?

Jerry: Although it’s a common process, there are a lot of companies doing injection molded part design that do not do mold flow analysis. Some people that build their own molds and are responsible for getting molds don’t have this service. A lot of design shops don’t have the experience to link part design with mold design and properly address how those two design processes marry together.

Not a lot of companies have this software and offer the link between evaluating things in the 3D world and the actual finished parts sitting on your desk. So, yes, this is one of Ferriot’s strengths, and it helps bring to life or show designers that aren’t that familiar with plastics, the issues that they may have created unintentionally.

Liz: I can see where this provides both an experience edge as well as a consultive edge when you’re working with our clients. I imagine that it’s especially helpful for designers that are not that familiar with injection molded parts. Is that correct?

Jerry: Right. For example, we get requests from startup companies or design houses that are industrial designers. They are looking for how a part is going to look or feel in their hands, but they haven’t taken into account how they’re actually going to make it. By coupling our experience with MFA, that gives them a check and balance, per se, of their design. A saying I saw long time ago is so true: “For every vision, there’s an equal and opposite revision.” We’re trying to help prevent those revisions from happening after the mold is built.

Liz: I imagine that it gets costly.

Jerry: Yes. Once the mold is built, every change you make to it, you’re looking at thousands of dollars. However, if we do an MFA with them before they started their mold, the little tweaks and changes are all but free. So, if you’re developing a new product and it includes injection molded parts, it pays to do your homework upfront. That’s where our expertise in consulting and working through part designs with the customer prior to mold build, pays for itself and is a value-added benefit that we provide.

Ferriot engineers consulting with customer on possible mold design improvements

Liz: How long has Ferriot been offering the mold flow analysis and the tool design?

Jerry: In-house, we’ve been doing it about 18-months, going on two years. Up until then, when we were awarded a project, we would have our mold makers do it for us. Basically, every mold that we would build, would have this analysis done on it. Now, we’re doing this analysis in-house, and we’re doing it at the quoting phase, or to double-check everything at the quoting phase.

We’ve actually been providing the analysis for years, either by contracting the service or having a tool shop do it for us and working with them to get the analysis done. Later in 2019, we made a significant capital investment to bring in the tool internally so we can perform the analysis here at Ferriot on our own, saving time and money, while providing better control over it.

Liz: How many Ferriot people are trained to utilize the MFA software?

Jerry: We have three tool engineers that are trained to perform the mold flow, mold filling analysis. We also have process engineers who, although they’re not trained to do it, they’re very familiar with it and help to interpret results and review results and act as resources for the tool engineers as the analysis is being done.

Liz: What are the typical problems that you find when you do the MFA?

Jerry: It’s best to start with product design problems that we might unearth, and then move into tooling. One problem that I’m working on with a customer, we got the test part in, we quoted it, and we were awarded the job. We ran a filling analysis and with their material and due to the wall thickness, the part wouldn’t fill. We tried multiple gating scenarios, to see if it would fill. It wouldn’t fill. I went back to the customer said, “Hey, this is the issue. We can’t do anything about it without changing the wall thickness.” Being proactive, we changed the wall thickness 20,000th of an inch and were able to fill the part. However, when we shared this solution with the customer, they said, “No, you can’t change the wall thickness.” The customer came back to us with three different resins. We ran the filling analysis and determined all three of them would work.

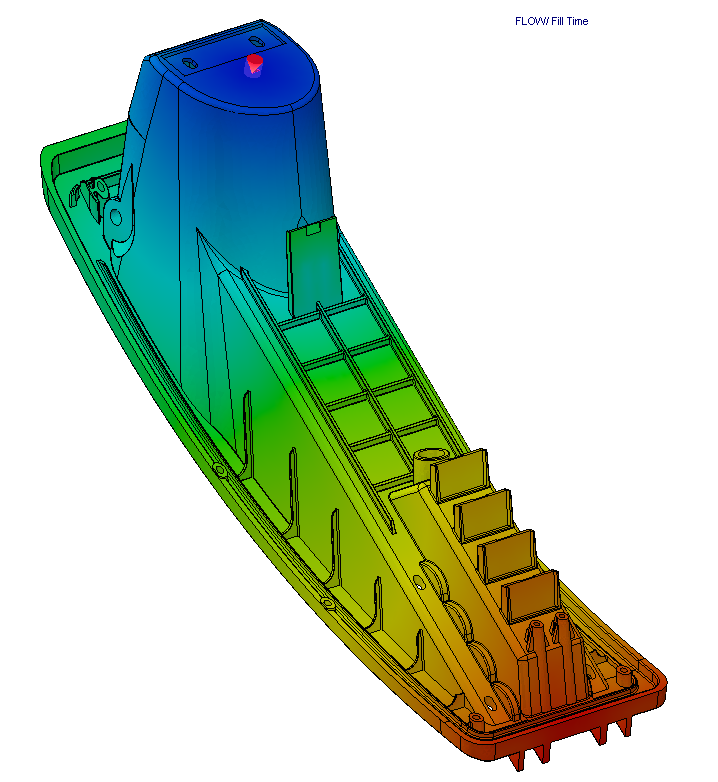

Example MFA simulation of nozzle boot flow fill time

But then they then came back to me later, “Well, we need to know if this is going to warp or not.” We then ran a warpage analysis on all three resins, and now they’re evaluating the warpage analysis to see which would be the best to use. So, thin wall thicknesses on parts or thin wall areas on parts could be bad, causing the material to somewhat hesitate as it flows through the part. Knowing that helps us advise the customer, “Hey, you have a part design problem here, you need to address it, and here are some ways to resolve it.” The filling analysis gives us a lot of vital information of possible problem areas on parts, including issues related to wall thickness. If a rim or something is too thick, the analysis will show us a sink or a little dimple on the outside surface of the part. We can show that to the customer and say, “Because this wall is really thick, you’re going to have a visual defect on the outside of that area.” Sometimes it’s okay, and they need the strength of that wall to be thicker, or “Oh, we didn’t realize that was so thick, let’s thin that down and see if we can get rid of that visual defect.”

Bottom line: There are numerous detailed reports within the results of the MFA, not only the answer to “will it fill properly?”, but it will identify areas that may not hold up under stress, where the hot spots or thick areas are in the mold. All of that data is available to review with our customers so they can alter their part design, if needed, to reduce or eliminate any problems.

Liz: Are there any interesting pain points that you guys were able to solve using this process? Are there any unique benefits that you’ve been able to offer customers because of having it, especially having it in-house?

Jerry: I immediately think of the value of being able to identify filling issues, even at the quote phase. If we are asked to quote a part, we can look at it and do it very fast analysis to identify filling issues that might stop the quote right there. We’d then let the customer know, “We can’t quote this the way it’s currently designed. We’ll have to talk about how to modify the design before we can provide a quote.”

A lot of customers aren’t even aware of these potential issues until we do our MFA. We’ve gotten quotes in from other people, and when we come back to them with this red flag, it kind of throws up a red flag of their own. Then they’ll ask, “Well, how did these other people quote it for us, and why didn’t they bring up this issue?” So, it helps get into the nitty gritty of quotes and parts early with customers, which gives the customer a good, comfortable feeling about Ferriot, that Ferriot’s providing them an extra service to help assure better parts. Hopefully, going that extra step helps us win their business.

Liz: How frequently do you find issues when you’re dealing with mold transfers?

Jerry: I can speak for myself that I don’t do a filling analysis on a mold transfer, unless we do have problems, but a lot of times there’s not a whole lot we can do. That mold is built, it’s been running production somewhere, and the customer is usually happy with the parts.

Now, if we have an issue with the part, you may be able to go back to the customer, run a filling analysis and say, “Hey, we’re having this issue because of this issue.” And I can show them the filling analysis of what’s happening with the plastic as it’s going around. Out of 50 transfer molds, that may happen once or twice.

Liz: So, the vast majority of mold flow analysis are done on parts in development, or molds in the tooling stage.

Jerry: Yes. It’s a simple engineering tool that helps you make the best decision before that mold is built. The cost of the software quickly pays for itself. If you miss something that you have to make a mold design change after the mold is built, it pays itself a couple of times over just by preventing those future costs.

Liz: Can you give me an example, a success story of how MFA saved costs?

Jerry: A very large customer of ours came to us with a new product, which is highly visible. They were very concerned about strength. We ran multiple filling analysis for them to try and manipulate where some weld lines were going to be. Weld lines, whenever they are formed, they’re weak areas of the part. We ran three or four analyses for them to get those weld lines moved: one, off a visual surface, and two, off of structural areas. If we wouldn’t have done that, this mold cost us in excess of $200,000, we probably would have been redoing half of it. So, that was an exceptional savings in both time and money.

Liz: That’s a great example! For those of us who don’t know, please explain what a weld line is?

Jerry: To make a hole on a plastic part, there has to be steel in that area of the mold. Imagine the plastic is flowing like a river. The piece of steel that’s in the mold to create the hole, think of that as a rock in the middle of the river. Now the water hits that rock, it has to flow around it, where the water comes together on the downstream side of the rock, or come together and welds itself back together, that’s what a weld line would be. It will fill in, but it’s not as strong. That’s a weld line. If you look at it closely, a tiny little line in the surface of the part. Eventually, as you get further away from the hole or further downstream, then the plastic starts flowing consistently again. But where it comes around that hole or the rock, it slams itself together.

By adjusting gate location, cooling, and other parameters, we can move the weld lines around in the part. When using the mold filling analysis, we can project where they are going to occur. The weld line is a slight visual imperfection, and it has a reduced strength. It’s important to the customer where that weld line is going to fall in part. By using MFA, we can predict where it’s going to occur and move it, if we don’t have to, by making adjustments to the tool design.

Liz: How would you summarize the mold flow analysis (MFA) process advantage?

Jerry: Simply stated, it’s an engineering tool that helps Ferriot and its customers make an informed and educated decision before moving forward with the development and creation of the actual mold, saving both time and money, while resulting in a stronger, higher quality end product.

If you have a question about mold flow analysis and how Ferriot can use it to help you with your next injection molded part tool design, feel free to contact us for a FREE initial consultation.