Injection molding is a widely used manufacturing process that produces plastic parts in high volume. Multiple industries rely on this process, including medical, electronics, automotive, agricultural and consumer products, to name a few. This highly efficient manufacturing method has a projected CAGR of 5.1% through 2027, for a potential market value of $240.9 billion.

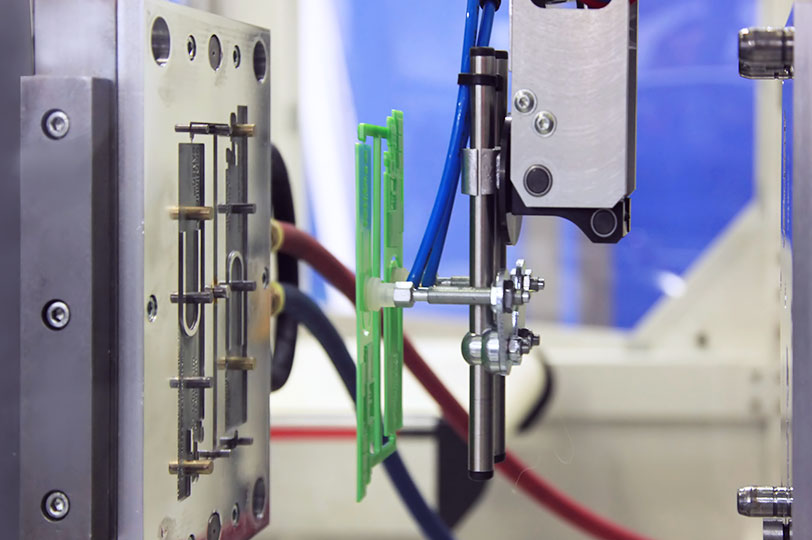

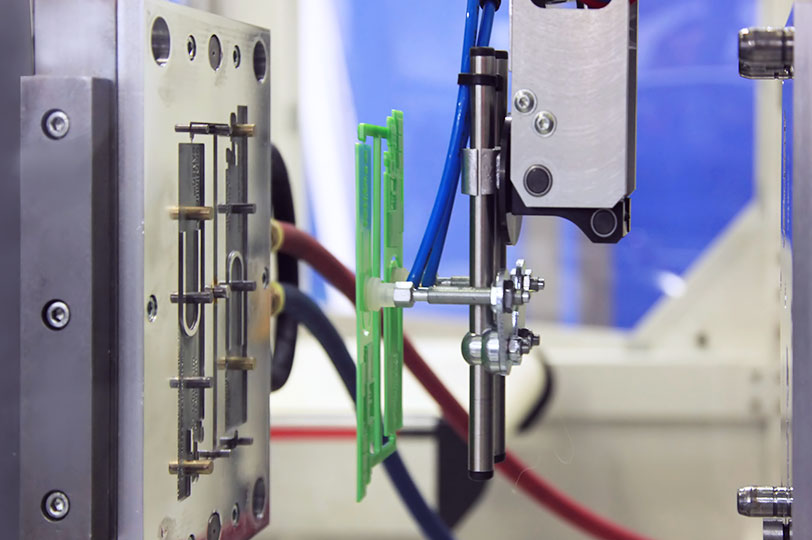

During injection molding, molten plastic material is injected into a mold cavity, allowing it to cool and solidify. When cooled, the parts are ejected. However, certain manufacturers new to the process might cool to the idea of injection molding after investigating the startup costs.

A careful examination of key phases of this process can help manufacturers more successfully navigate this cost challenge. These can include the total cost of ownership, the importance of resin selection during the planning phase, design for manufacturability and secondary operations. This examination can help determine whether injection molding is a viable alternative for a new project proposal and will supply the desired return on investment.

A careful examination of key phases of this process can help manufacturers more successfully navigate this cost challenge. These can include the total cost of ownership, the importance of resin selection during the planning phase, design for manufacturability and secondary operations. This examination can help determine whether injection molding is a viable alternative for a new project proposal and will supply the desired return on investment.

Most manufacturers look at total cost of ownership over the long term

Total cost of ownership (TCO) represents a crucial metric in manufacturing that considers all the expenses associated with a product or part over its entire life cycle. For injection molding processes, TCO includes costs such as the price of the mold or tooling costs, the cost of the particular resin specified for the part, and the average cost of manufacturing as a price per piece basis over the projected product lifecycle.

The cost of the mold can be significant, and it is essential to consider its expected lifespan and the volume of parts it can produce, to calculate its actual cost. The price per piece is calculated using factors such as the material used, the part complexity, the number of units produced per run and the setup costs associated with each individual run.

Finally, resin costs can represent up to 50% of the total part cost. Resin choice impacts a variety of factors per project. For example, when the part is required to withstand exposure to UV rays or needs chemical resistance capabilities, this will restrict resin choices to thermoplastics that offer these characteristics.

The higher cost of setup and tooling associated with injection molding compared to other plastic technologies often restricts the process to companies that make parts with larger volumes, from the thousands to the millions. Certain specialty parts in smaller quantities that meet a specific market need also take advantage of injection molding. Tooling, resin selection, part quantities and overall volume over the course of two to three years can supply manufacturers with a reasonable expectation for total cost of ownership to compare pricing.

The importance of proper resin selection for injection molding

When it comes to selecting the right resin for injection molding, there might not be a more crucial factor impacting the project cost. The resin itself often dictates conditions of tooling or mold making. Molds are constructed according to mold flow analysis of the resin choices and desired properties. Once this mold flow analysis is conducted and the tooling created, its performance is linked to the specific resin analyzed for that mold.

Factors involved in resin selection will include the material’s:

- Heat deflection temperature

- Ductility

- Brittleness

- Shrinkage

- Chemical compatibility

For example, when producing injection molded parts destined for use on gasoline dispensers and pumps, the resin must exhibit a high resistance to the chemicals present in gasoline.

Resin costs typically account for approximately 50% of the total project cost. Prior to making the mold or tooling, companies new to injection molding can consult with the engineers at an experienced partner such as Ferriot, to discuss resin alternatives based on the properties desired in the finished product.

Engineered resins can cost as much as $10.00 per pound or more, while lower-cost commodity resins like PVC, polypropylene, or high-density polyethylene can be less expensive. The best time to determine resin options is early in the planning stages.

Part of resin selection is also looking at resin availability, location of the producer and/or distributor(s) and lead time. Resins that are more widely used pose less supply chain risk. One might consider supply agreements for highly specialized resins or blends. It is also suggested to qualify more than one resin in the tool as a backup to provide insurance against any future supply issues.

Tooling costs

The cost of tooling is a critical factor in the injection molding process and can vary widely depending on the size and complexity of the mold. While purchasing tooling from vendors in the Pacific Rim may offer cost savings, manufacturers also need to consider all factors involved with ordering tooling from overseas.

There is typically a longer transit time for overseas tooling that can stretch from eight to twelve weeks for oceanic shipping. Some customers will cover the cost of air freight to reduce lead times, although this adds to the expense.

There are additional concerns about intellectual property being compromised, particularly when dealing with vendors located in countries like China, Vietnam, or Korea.

Alternatively, tools made in North America, particularly in the US and Canada, are more expensive but offer a quicker turnaround time and greater assurance that intellectual property rights will be protected. Companies in highly competitive markets where proprietary business practices weigh more heavily, such as medical instrumentation, electronics and semiconductors for example, are most concerned about protecting intellectual property. Manufacturers must carefully weigh these factors when considering the cost of tooling and where that tooling is created, for risk mitigation and as part of total cost of ownership.

The cost of the mold is one of the biggest barriers for market entry for some startup companies. Someone new to injection molding might not be aware that the mold can cost anywhere from $30,000 to more than $600,000 depending on the size.

Another design option to lower costs over time for projects with large production runs is to consider a multi-cavity tool. This allows multiple parts to be produced at a given time. The initial cost of a multi-cavity mold might be higher than a single cavity; however, this can be amortized over the mold’s life.

Production run frequency and sizing

After the tooling, when creating or producing a product run, there are the injection molding machine cost which includes utilities, labor and setup. This typically comprises 30% of a project cost. The setup is a fixed cost and remains the same regardless of whether a customer produces one or one thousand parts.

Additionally, the production lot quantity is another cost bucket, which refers to the total quantity of parts produced in a single production run. Ferriot often runs on a 60-day cycle, producing the quantity required by a company for that time period. This balances the setup costs and labor with warehousing and storage.

The size of the production run can help amortize the setup costs, or the labor involved in installing the mold into the press. Certain molds might take an entire day to set up. In other cases, a heavy mold of 40,000 pounds for example, might require an overhead crane to move into position. Mold set up requires time and takes an experienced, sophisticated team.

A better understanding of these cost components can help manufacturers make well informed decisions to optimize production and reduce costs.

Work with injection molders that provide value-added, secondary services

One of the key advantages of working with Ferriot is its ability to offer a wide range of finishing operations all under one roof. This reduces the complexity of the supply chain for customers that might otherwise need to ship parts to multiple locations for services such as painting, pad printing, or the insertion of metal components.

Ferriot has built a reputation in the industry for these services and most customers take advantage of these finishing operations. A comprehensive approach to plastic part fabrication can help save customers time and money by streamlining the production process.

The engineering team at Ferriot is also available to consult on design for manufacturing (DFM). Typically, the customer will specify a resin preference according to the design brought into the shop. On occasion, the part’s design will not suit the injection molding process. The Ferriot team can supply suggestions for design modifications when drafts or undercuts might limit the ability of the part for injection molding.

Companies of all sizes trust Ferriot for injection molding and value-added finishing services. The company makes every effort to overcome supply chain issues by leveraging its relationships with multiple suppliers. By investing in spare parts to keep machinery in top working order and increasing its stock of resin, Ferriot can help customers maintain project timelines. Call Ferriot today to discuss your next injection molding project.