How selecting the right design specs, resin and molding process can answer them

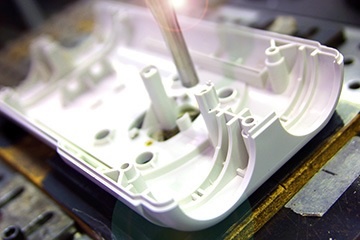

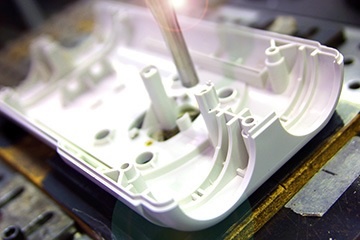

Injection molding is a highly-engineered process, and demand for it only continues to grow as more manufacturers replace traditional materials like wood, steel and fiberglass with thermoplastic resins that are lighter in weight but just as durable. Applications and uses for injection molded parts are numerous and expanding, with increased use in the medical, automotive, industrial, housewares, electronics industries, to name a few.

If you’re thinking about a conversion to resin injection molding, you may have questions about the quality of the finished part, what specs to design to, or what process is right for your application. Here are three common questions to ask that can help put your project on the right track from the beginning.

What specs do I design toward?

For most of our projects, they come down to understanding impact resistance on your part, heat exposure and color.

Impact Resistance

At Ferriot, once we know why impact resistance is important and the type of expected impact load (e.g., a fall onto a hard surface from 5 feet, or having loads dropped on it, etc.), our “upfront” impact testing offers valuable insights. By using molds that are similar to the final part, we can produce prototype parts using an array of resins, and then compare their impact resistance. We also conduct Notched Izod tests to measure impact performance expressed in energy lost per unit of thickness at the notch, based on ASTM D256 standards.

Heat Exposure

Your injection molding partner should also pre-test to determine the Heat Deflection Temperature (HDT), the temperature at which a plastic sample deforms under a specified load. The tests should reveal the maximum temperature the part can withstand without deformation.

Other heat exposure-related issues to consider for your part include knowing the type of heat source the part would be exposed to, i.e. a flame, sun exposure or heating element. You and your injection molder can also avoid heat exposure issues by knowing whether the part will be subject to interference with other materials. For example, dissimilar materials have considerable thermal expansions or contractions and may cause an interference condition.

Color Accuracy

The good thing about injection molded thermoplastic parts is the ability to ensure consistent color throughout the part with the right pigment to resin ratio. The problem can arise when trying to match a prescribed color standard. Even with the standard met, you could face the issue of color retention through UV, light and thermal exposure.

At Ferriot, we will test a number of pigment-resin formulas to make sure the resulting color matches your brand identity guidelines.

What resin is the right choice for my application?

Speaking of resins…the right choice of thermoplastic resin can alleviate many issues associated with impact resistance, heat exposure and color accuracy of injection molded parts.

Thermoplastic resins come in two basic classes: engineering grade resins and commodity resins. Here are a few resin types that meet impact, heat and color requirements.

Engineering Grades

- Nylon – tough, superior thermal and chemical resistance

- Polycarbonate – strong, good temperature range, transparent

- ABS – good impact strength, surface quality, colorability and rigidity

- Structural Foam – good weight-to-stiffness ratio

Commodities Grades

- Polystyrene (PS) – lower cost, wide range of impact, good clarity and rigidity

- Polyvinyl chloride (PVC) – can be colored, naturally flame retardant

Process matters: Which injection molding technology can overcome common issues?

With a few exceptions, Ferriot can accommodate almost any thermoplastic resin and nearly any design specifications.

Depending on your part’s requirements, traditional injection molding, structural foam injection molding, gas-assisted injection molding or overmolding – all processes available at Ferriot – will suit a wide range of applications.

The answers to those three questions involve a lot of complexity that you’ll want to discuss more with your contract manufacturing partner. We’ve compiled some additional questions to ask, along with a variety of checklists, to help with your injection molding journey. To read more about how to optimize the injection molded parts development process, download our free guideline, “Designing Injection Molded Parts: A Handbook for Designers & Engineers.” Or, if you prefer, call us at (330) 786-3000 for immediate attention.