Expert Consumer Product Injection Molding

Consumer Product Injection Molding

With over 90 years of experience, Ferriot has a long history of making a variety of consumer products and continues to update its portfolio to include the more complex consumer appliances and electronics of today.

Our consumer product injection molding experience includes:

- Engineering expertise with complex geometries

- Cosmetic enclosures and skins

- Painting and branding capabilities

- Assembly, packaging and drop shipping

Ferriot has an interesting and varied history in consumer products. We were there at the onset of injection molding being used in mass production of consumer goods and we have some great stories to tell.

- In the mid 1940’s Ferriot spent a great deal of time working for the toy industry with companies such as Disney, Mattel and Kenner.

- We made the first Mickey Mouse, Minnie Mouse, and Donald Duck characters produced by injection molding.

- Barbie and some of her accessories were also made here.

- For over a decade, Ferriot manufactured dolls, model planes, ships cars, rocking horses and other novelties.

- In the 1950’s and 60’s, Ferriot became a major supplier of highly detailed plastic components for furniture, including console television components for Zenith, RCA and Admiral, cabinetry, chair backs and ornate legs.

- Later, in the 70’s, Ferriot created molds for the collectable Star Wars figurines and housing for the first IBM personal computer.

As manufacturing for these items moved overseas, the company focused on more complex parts including appliances, home office equipment and even polypropylene siding.

Ferriot continues to reinvent itself to meet current consumer market needs focusing on where we can compete for business where the desire for US made products has been increasing. Our engineering services include DFM, mold design and mold manufacturing. Our range of injection molding machine tonnage allows us to take on entire product programs with numerous part sizes. With many valued added capabilities, the entire product can be inserted, machined, welded, assembled, painted, labelled and packaged here. By keeping more processes at one location, we help our customers save on freight and lead times.

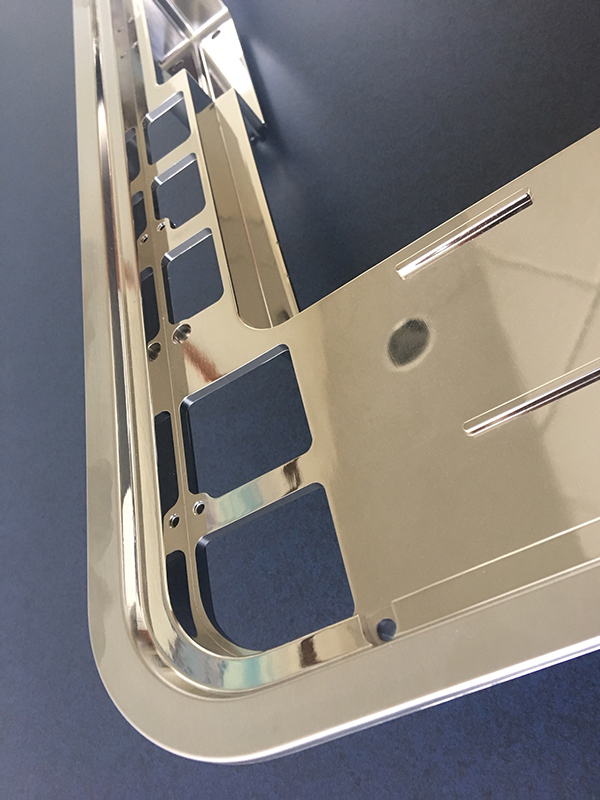

White Paper Creating Injection Molded Parts That Shine

Learn the considerations of successful chrome plating

Read the White PaperCase Studies

How can we help?

Ferriot’s experienced engineers are here to guide you through every critical step in your injection molding journey, from concept to completion.