Detailed Plastic Product Testing

Plastic Product Testing

Efficient Plastic Product Testing for High Quality Standards.

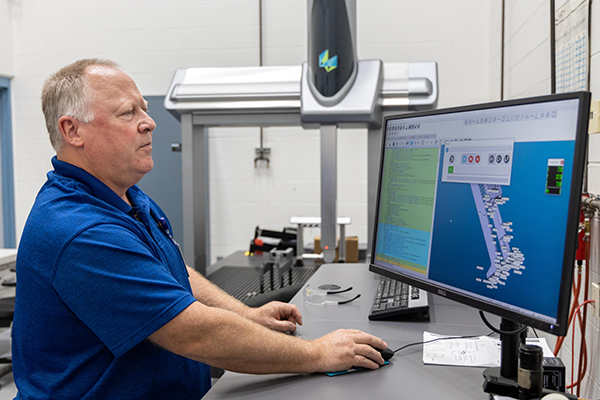

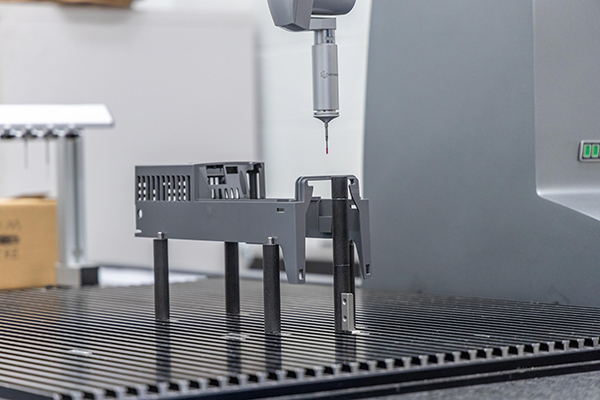

Whatever a customer needs to meet quality standards on a finished assembly or product, we develop a scheme for meeting those requirements through product testing.

Depending on the complexity of the assembly, we may test every product that comes off the assembly line — or maybe every tenth product, if we’re dealing with less-complicated assemblies.

If an assembly includes multiple, complex components, we customize an inspection plan for each of those components. For example, a circuit board requires a higher level of quality control than sheet metal or plastic component. Each product or subassembly that comes off our line has a product identification number that makes it traceable by lot. Our product testing procedures are recorded to tie back to each lot. Read the case study Contract Manufacturing for Digital Printers to learn more.

We may test every product that comes off the assembly line…

Institutional Experience

Even if you don’t know us, you’ve probably touched our products — in banks, at gas pumps and in offices, industrial facilities and hospitals.

Our expertise includes engineering, product design, injection molding, custom molding, sub- and finished assembly and the on-time delivery of components and finished products for major industry. We streamline the total manufacturing process from start to finish, from supply-line development and management, process qualification, product testing and final assembly, all the way to drop shipping.

With mobile, adaptable manufacturing modules, Ferriot tailors on-time production to vastly different needs, including short runs on assemblies with multiple parts.

Tip Sheet Contract Manufacturing Guidelines

Download Tip SheetCase Studies

How can we help?

Ferriot’s experienced engineers are here to guide you through every critical step in your injection molding journey, from concept to completion.