Trusted EMI / RFI Shielding

Trusted EMI / RFI Shielding

Efficient Processes. Quality EMI / RFI Shielding Standards.

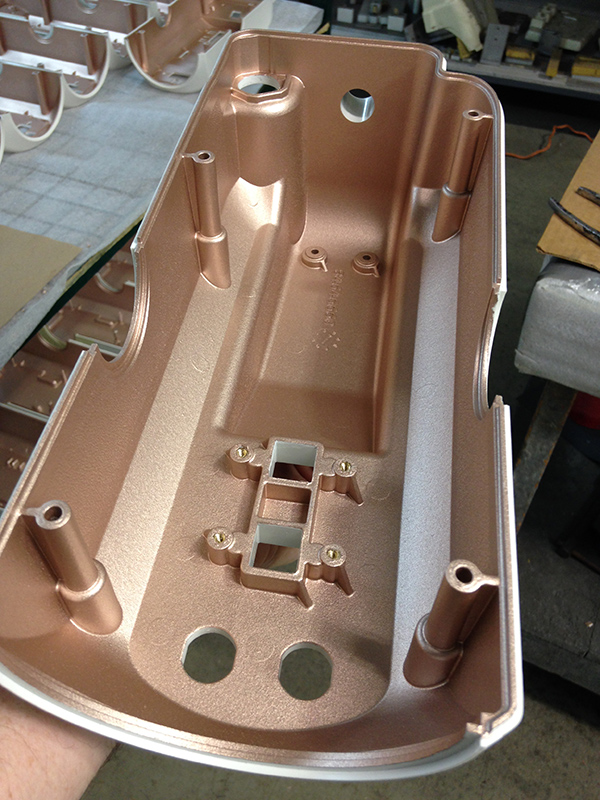

At Ferriot, we have been shielding medical equipment and other devices for more than 30 years — protecting devices from electromagnetic and radio-frequency interference with EMI RFI Shielding.

We wet spray with nickel-based, copper-based and silver-based conductive paint, depending on the performance required. From our pioneering work in the medical field, we moved naturally into protecting sophisticated business and technical equipment as well.

We use a combination of stainless and urethane nests and paint masks to make sure that shielding covers only the required areas.

Our HVLP shielding system relies on recirculating pots to maintain the proper electrical properties.

Masks are cleaned on a frequent basis at a solventless washing station.

Our traceable, quality-control testing ensures that the conductivity specifications of our customers are met.

No shielding job is too large or too small for our operation.

About Finishing Operations at Ferriot

At Ferriot, we deliver finished products and subassemblies on time to any location.

The advantage: Our customers avoid the hassle of dealing with multiple suppliers of parts and pieces. Instead, they receive just the finished assemblies they need — whether simple or complex — meeting their manufacturing needs and their delivery deadlines.

The versatility of our skilled workforce differentiates Ferriot. Our workers cross train for multiple jobs, allowing us to balance work flow for maximum efficiency. Workers routinely shift from assembly lines to paint stations, for example. With factory workers averaging more than 20 years of experience each, our talent pool covers a full range of core competencies:

- Finished painting

- EMI/RFI shielding applications

- Cosmetic coatings

- Ultrasonic welding

- Hot stamping

- Heat staking

- Pad printing

Call us to learn more about EMI RFI Shielding.

FAQ

What is emi rfi shielding?

EMI/RFI shielding refers to the process of protecting electronic devices from electromagnetic interference (EMI) and radio frequency interference (RFI). This shielding is crucial for ensuring the proper functioning of electronic components and preventing disruptions caused by external or internal electromagnetic waves.

Case Study Finishing Operations For Medical Equipment

Read The Case StudyCase Studies

How can we help?

Ferriot’s experienced engineers are here to guide you through every critical step in your injection molding journey, from concept to completion.