Digital Printing on Plastic Products

Digital Printing on Plastic Products

At Ferriot, we have the ability to add vivid, high quality digital images directly to your plastic products! This technology eliminates the need to apply adhesive labels, and it even works on curved surfaces. Digital printing provides vibrant color that is durable, weatherproof and chemical resistant.

Customization

Custom digital images printed on your injected molded parts is the latest way to enhance the look and improve branding of your products.

Aside from logos and images, customization is also available when there is variable data and different markings that need to be applied to different part. Specialty markings can include individual names, barcodes, serial numbers, lot numbers and expiry codes.

Printing on Plastic Products with Our Digital Printer

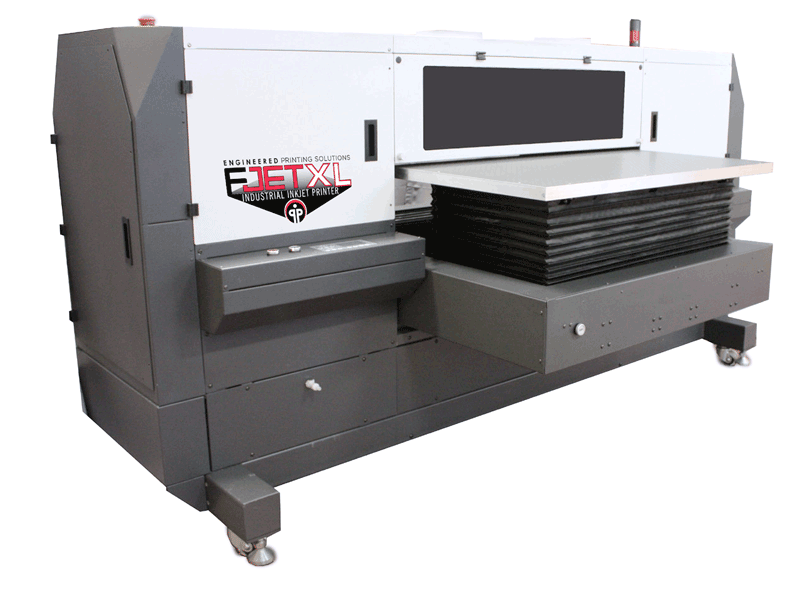

The FJETXL delivers vivid colors and fine details.

How does one print on non-porous substrates?

To print on non-porous substrates, Ferriot uses specialized, rapid curing UV inks. Once the ink is applied, a UV light stabilizes and cures the ink, resulting in a strong polymeric layer. UV inks are found to be more chemical and scratch resistant than solvent based inks due the increase in hardness once cured.

The process is capable of creating high quality images up to 1200 dpi. With a large printer bed, Ferriot provides a maximum print area of 41.25” x 24” and the ability to print on objects up to 12” tall.

Our color management software supports Pantone color matching and allows cyan, magenta, yellow and key to print simultaneously, along with white. The flexible artwork requirements include the ability to print from these files: EPS, PDF, JPG, TIFF, as well as native Adobe AI and Illustrator files.

This process works very well with ABS and styrenes, as well as polycarbonates and Lexans. There are other materials that are more challenging, but pretreatments options are available to increase the surface tension of the plastic and improve ink adhesion.

Key:

Image resolution

Max 1200 dpi

Image size

Max 41.25″ x 24″

Object height

Max 12″

Color specs

CMYK – Pantone match

Artwork requirements

EPS, PDF, JPG, TIFF, Adobe formats

Workbook Resin Selection

When designed intelligently, injection molded parts can offer product designers durable, light-weight, and cost-effective alternatives to metal parts. But ensuring that an injection molded part lives up to this potential depends in large part on choosing the best resin. This workbook details different part characteristics and how they influence your resin choice.

Download The WorkbookCase Studies

How can we help?

Ferriot’s experienced engineers are here to guide you through every critical step in your injection molding journey, from concept to completion.